Ansys Polyflow®

Overview

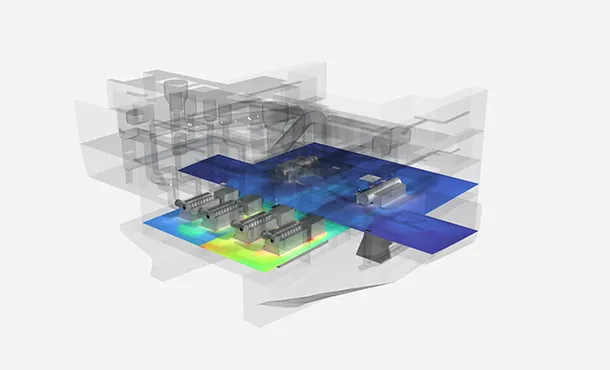

Ansys Polyflow® excels in simulating the behavior of polymer processing, glass forming, and food processing.

It enables users to model complex flow and thermal behaviors, helping to enhance material properties and manufacturing processes.

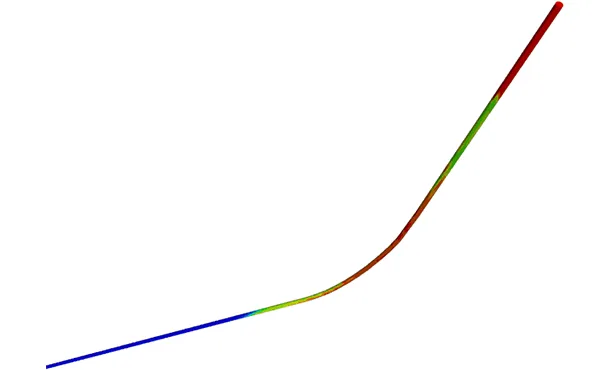

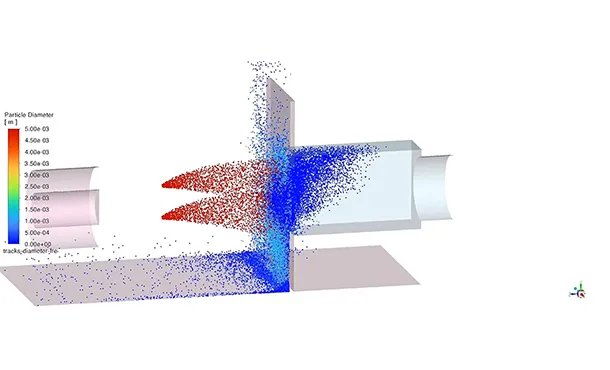

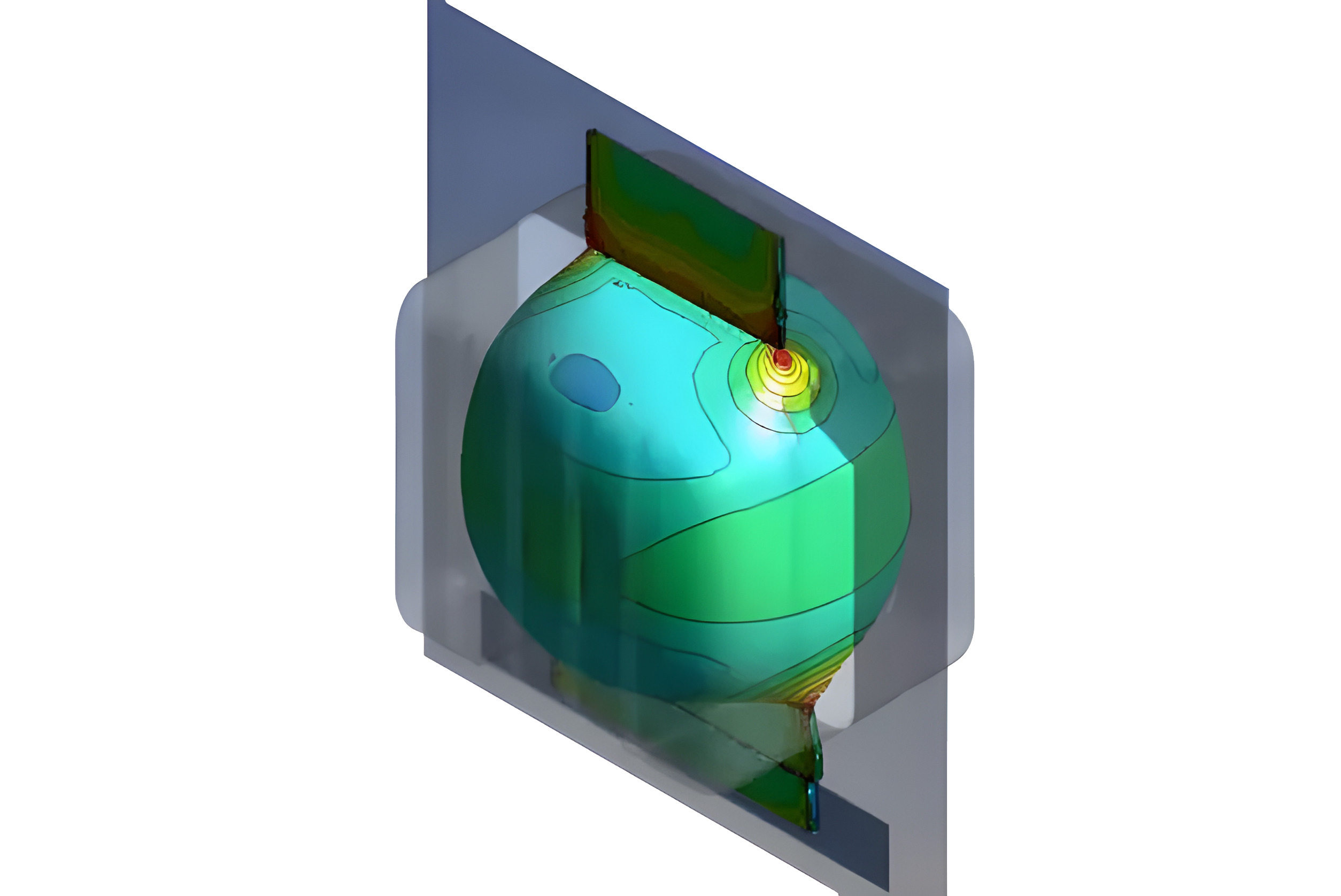

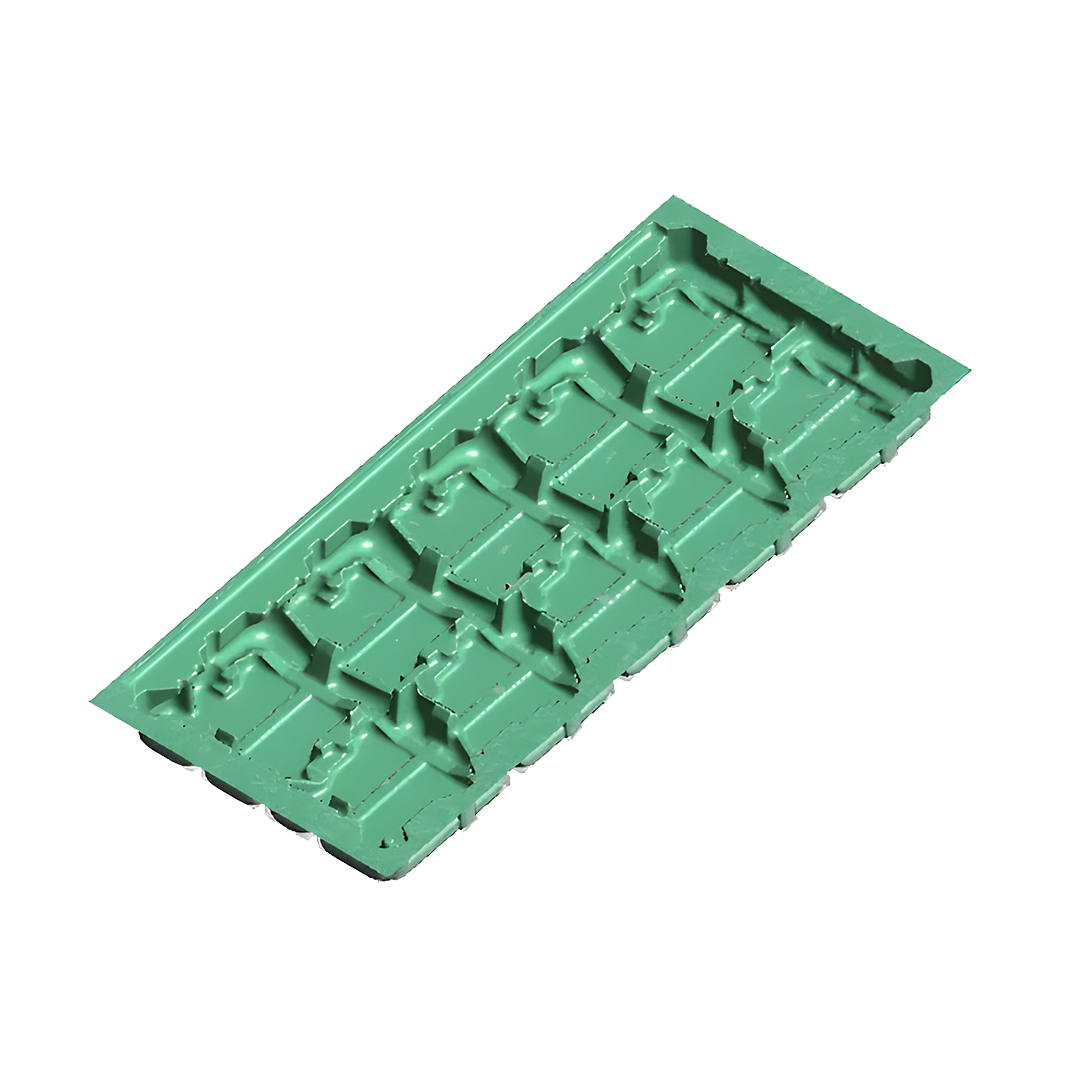

With Ansys Polyflow®, you can perform detailed simulations of extrusion, thermoforming, blow molding, and fiber drawing, ensuring that products meet stringent quality standards and perform as intended.

Why Ansys Polyflow®?

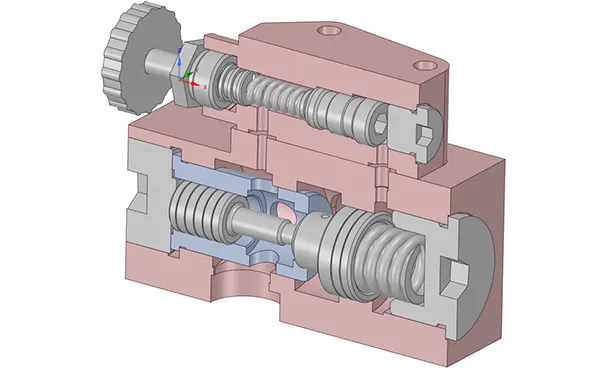

Advanced Rheological Modeling

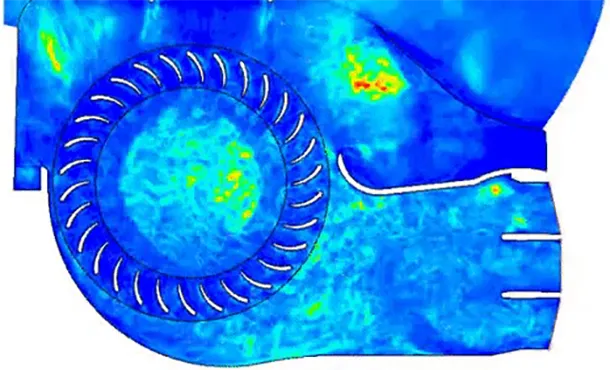

Simulate complex material behaviors, including viscoelastic and non-Newtonian fluids, to predict and optimize flow patterns.

Process Optimization

Use simulation results to refine manufacturing processes, reducing waste and improving product quality.

Thermal Analysis

Analyze the thermal effects on materials during processing to ensure optimal temperature control and material properties.

Customizable Simulation Tools

Tailor the simulation environment to specific needs, allowing for precise control over the modeling process.

High-Performance Computing

Leverage parallel computing capabilities to handle large and complex simulations efficiently.

Why partner with Simtec?

Partnering with Simtec for your Ansys Polyflow® needs offers several advantages:

- Expert Support

- Comprehensive Training

- Cost-Effective Solutions

- Tailored Services

Applications Across Industries

Ansys Polyflow® is utilized across a wide range of industries to improve material processing and product performance.